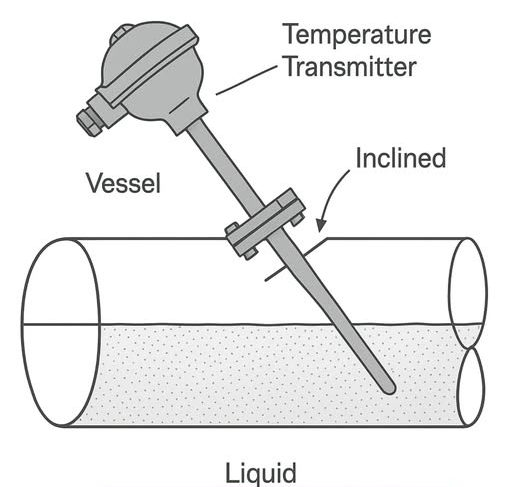

Optimal Mounting Practices for Temperature Transmitters: Why Angled?

In industrial environments, it is not uncommon to see temperature transmitters installed at an angle rather than in a straight vertical position. This is not a matter of convenience or installer preference—it is a well-considered design decision rooted in engineering best practices. In this blog post, we will explore the key reasons behind angled installation and why it matters for long-term performance and reliability.

1. Preventing Condensation Build-Up

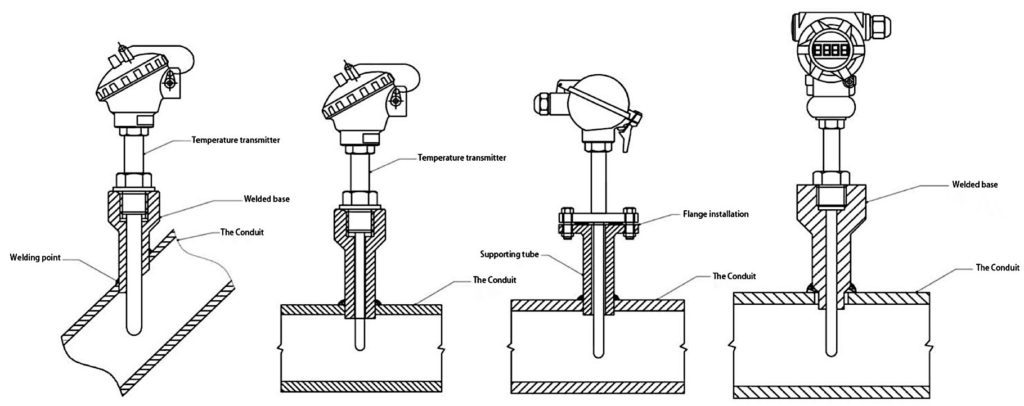

In humid environments or locations with large temperature fluctuations, condensation is a common issue. When a temperature transmitter is installed vertically, moisture can collect around the sensing element inside the thermowell or probe housing.

Installing the transmitter at an angle allows condensation or water to drain away naturally, reducing the risk of measurement errors and internal corrosion.

2. Reducing Mechanical Stress on the Instrument

Temperature transmitters are often mounted on high-temperature pipes or equipment surfaces. Vertical installations place the full weight of the transmitter and the sensor directly on the connection threads or flange, which can lead to mechanical fatigue over time.

Angled installation distributes mechanical stress more evenly and protects the sensor from vibration and thermal expansion-related damage.

3. Improving Display Visibility and Maintenance Accessibility

Many temperature transmitters come equipped with local digital displays (such as our ZINACA intelligent temperature transmitter series). Angled mounting improves visibility for operators and makes maintenance tasks more ergonomic.

Typically, an installation angle between 30° and 45° is ideal for easy data reading and tool access.

4. Enhancing Response Time and Measurement Stability

In fast-changing process conditions, sensor placement is critical. The insertion angle of the temperature probe affects how quickly and accurately it can detect temperature variations in the process medium.

An angled probe can ensure better contact with the medium flow, resulting in faster and more stable readings.

5. Following Industry Standards and Best Practices

In sectors like petrochemicals, metallurgy, power generation, and pharmaceuticals, angled installation is often recommended by design codes and engineering standards.

This approach is not only about optimizing measurement performance—it’s also about ensuring safety, long-term reliability, and ease of operation.

Conclusion

What may appear to be a small installation detail—mounting angle—actually plays a vital role in the overall accuracy, reliability, and longevity of a temperature measurement system. At ZINACA, we understand that performance lies in the details. That’s why we design and manufacture our temperature transmitters with real-world applications in mind and offer full technical guidance to support optimal installation and operation.

For more information about our temperature transmitter product lines or to get expert support for your application, please visit our website: www.zinaca.net or contact us at zinacaoverseas@gmail.com

Click to consult us

Click to consult us