Boosting Performance: Vortex Flow Meter Maintenance & Efficiency

How Proper Maintenance Enhances Accuracy and Longevity

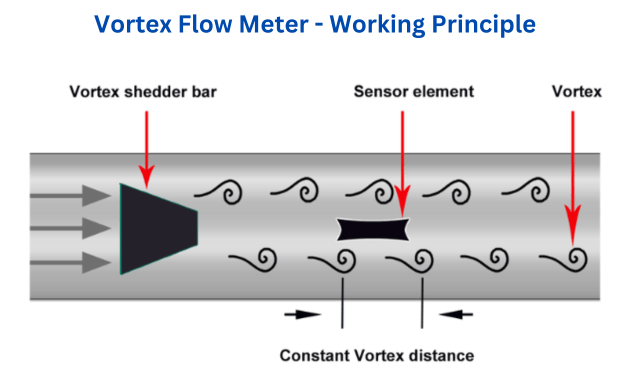

In modern industrial processes, vortex flow meters are widely used for their reliability, low pressure loss, and ability to handle a wide range of fluids—liquids, gases, and steam. However, like any precision instrument, a vortex flow meter’s performance is heavily influenced by how well it is maintained. In this article, we explore how regular maintenance can enhance both efficiency and accuracy, ultimately reducing operational costs and extending product life.

What Affects the Efficiency of Vortex Flow Meters?

The efficiency of a vortex flow meter refers to how accurately and reliably it measures flow over time with minimal maintenance, signal interruption, or downtime. Several factors can impact this:

Deposits and contamination in the sensor or flow path

Vibration and pipeline stress affecting measurement stability

Temperature and pressure extremes influencing signal quality

Improper installation (e.g., insufficient straight pipe length)

These issues can lead to drift, false readings, or even sensor failure if not addressed through proper maintenance.

Best Practices for Vortex Flow Meter Maintenance

Regular Visual Inspection

Check for dirt, corrosion, or leaks around the meter housing and sensor probe. A quick monthly check can help catch issues before they impact performance.Clean the Shedder Bar and Flow Path

Build-up of scale or residue on the bluff body (shedder bar) can distort the vortex signal. Periodic cleaning with appropriate solvents or mild brushing is recommended—especially in steam or dirty liquid applications.Check Electrical Connections

Verify that wiring, signal cables, and grounding are intact. In harsh environments, connectors can loosen or corrode over time.Monitor Zero-Flow Baseline

When there is no flow, the output should be zero. Any significant drift at zero flow may indicate sensor malfunction or buildup.Calibrate Periodically (if required)

Although most vortex meters are factory-calibrated and stable over time, critical applications may benefit from scheduled recalibration to ensure traceability.Use Filters and Strainers if Necessary

In processes where solids or moisture are present, install upstream filters to protect the meter from mechanical damage or signal interference.

How Maintenance Enhances Efficiency

Prevents unplanned downtime

Early detection of wear or fouling prevents flow disruptions and costly shutdowns.Maintains long-term accuracy

Accurate data means better process control, reduced waste, and optimized energy use.Extends service life

Proper care reduces mechanical stress and keeps electronics functioning longer.Improves safety

In high-pressure or steam applications, leakage or sensor failure can pose risks. Maintenance ensures continued safe operation.

Zinaca’s Commitment to Reliable Measurement

At ZINACA, we understand that reliability is everything. That’s why our vortex flow meters are designed with durable stainless steel bodies, robust electronics, and optional self-diagnostic functions. Our technical support team also provides installation guidance, maintenance tips, and spare part supply to help ensure your system runs at peak performance—day after day.

Conclusion

A vortex flow meter is only as reliable as the maintenance behind it. By implementing a regular inspection and cleaning schedule, facilities can greatly boost the efficiency, safety, and return on investment of their measurement systems. Whether you operate in oil & gas, chemicals, or energy, maintaining your vortex meter is a smart and necessary move.

Want to learn more? Contact us at zinacaoverseas@gmail.com or visit www.zinaca.net for product catalogs and technical support.

Click to consult us

Click to consult us