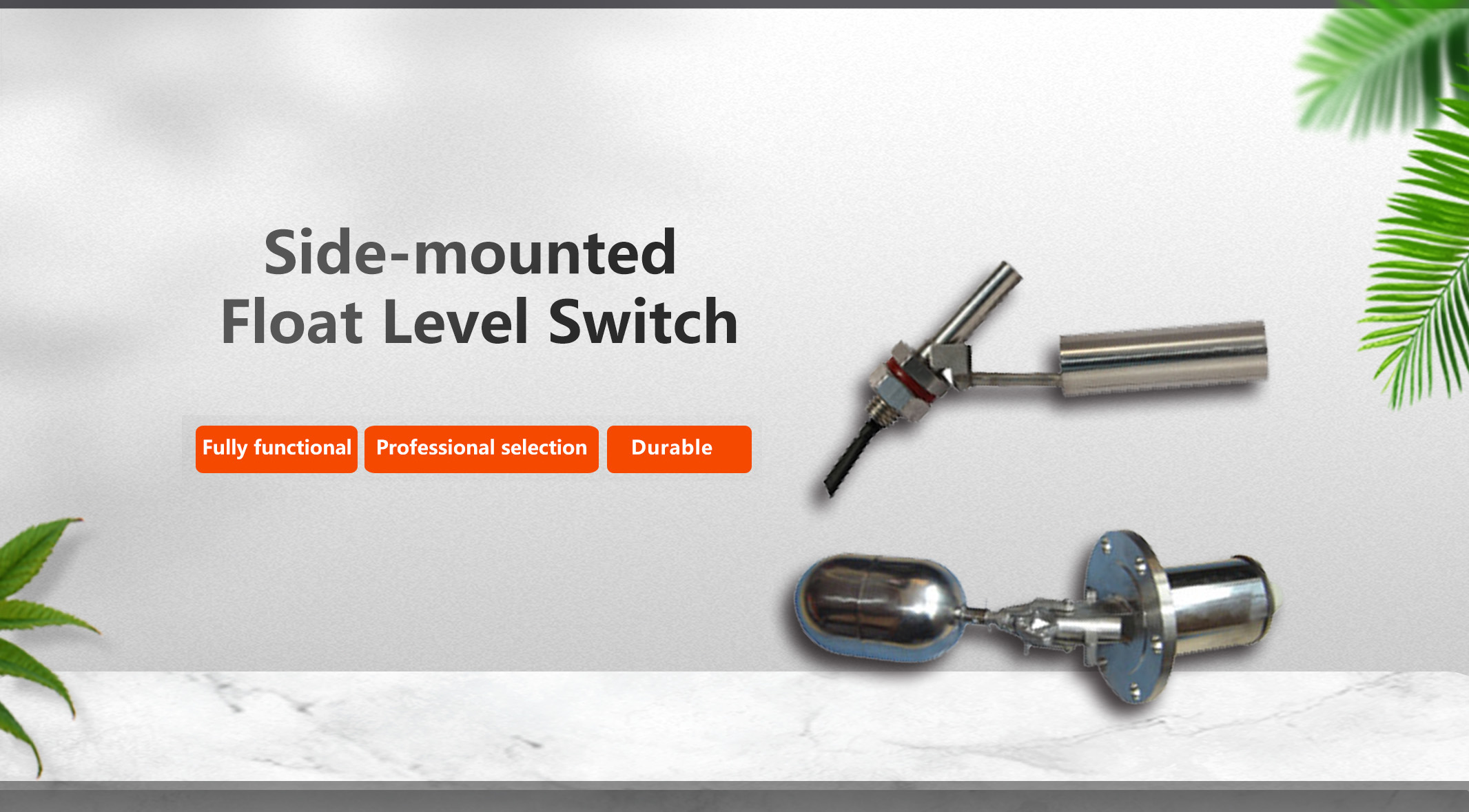

The side-mounted float switch provides reliable liquid level detection using a float-actuated mechanism. As the float rises or falls with the liquid level, it reaches a 20-degree tilt, triggering a lever arm movement. This motion actuates a microswitch or magnetic reed switch, toggling between Normally Open (NO) and Normally Closed (NC) states to control circuits. Designed for accurate level monitoring, it is ideal for industrial applications such as water treatment, chemical processing, oil storage, and food production. With a durable and corrosion-resistant design, it ensures long-term stability in harsh environments.

Product Features:

Flexible Installation Options: Can be installed horizontally on the side wall or vertically on the top of the tank, offering versatility for various tank configurations.

Wide Voltage Support: Compatible with both 220VAC and 24VDC circuits, ensuring broad application possibilities.

Isolated Control System: The control unit is completely isolated from the liquid medium, preventing direct contact for improved durability and safety.

Material and Connection Variety: Available in a wide range of materials and connection methods, ensuring suitability for different environmental conditions.

Durable and Compact Design: Lightweight and space-efficient, designed for long-term operation without compromising performance.

Technical Parameters:

Maximum Pressure:

Standard: 10 MPa

Compact: 10 bar

Medium Temperature: Maximum: 350°C

Density of the Medium: ≥0.75 g/cm³

Output Signal: Switching output

Contact Capacity:

Compact: 220VAC, 5A, SPDT

Standard: 220VAC, 5A, SPDT

High Temperature: 220VAC, 1A, SPDT

High Temperature Dissipation: 220VAC, 5A, SPDT

Corrosion Resistant: 220VAC, 5A, SPDT

Protection Class: IP65

Explosion-proof Grade: Ex d II BT6, Ex d II CT6

Material Options: SUS304, SUS316, PP available

Process Connection: Threaded or flanged connections available